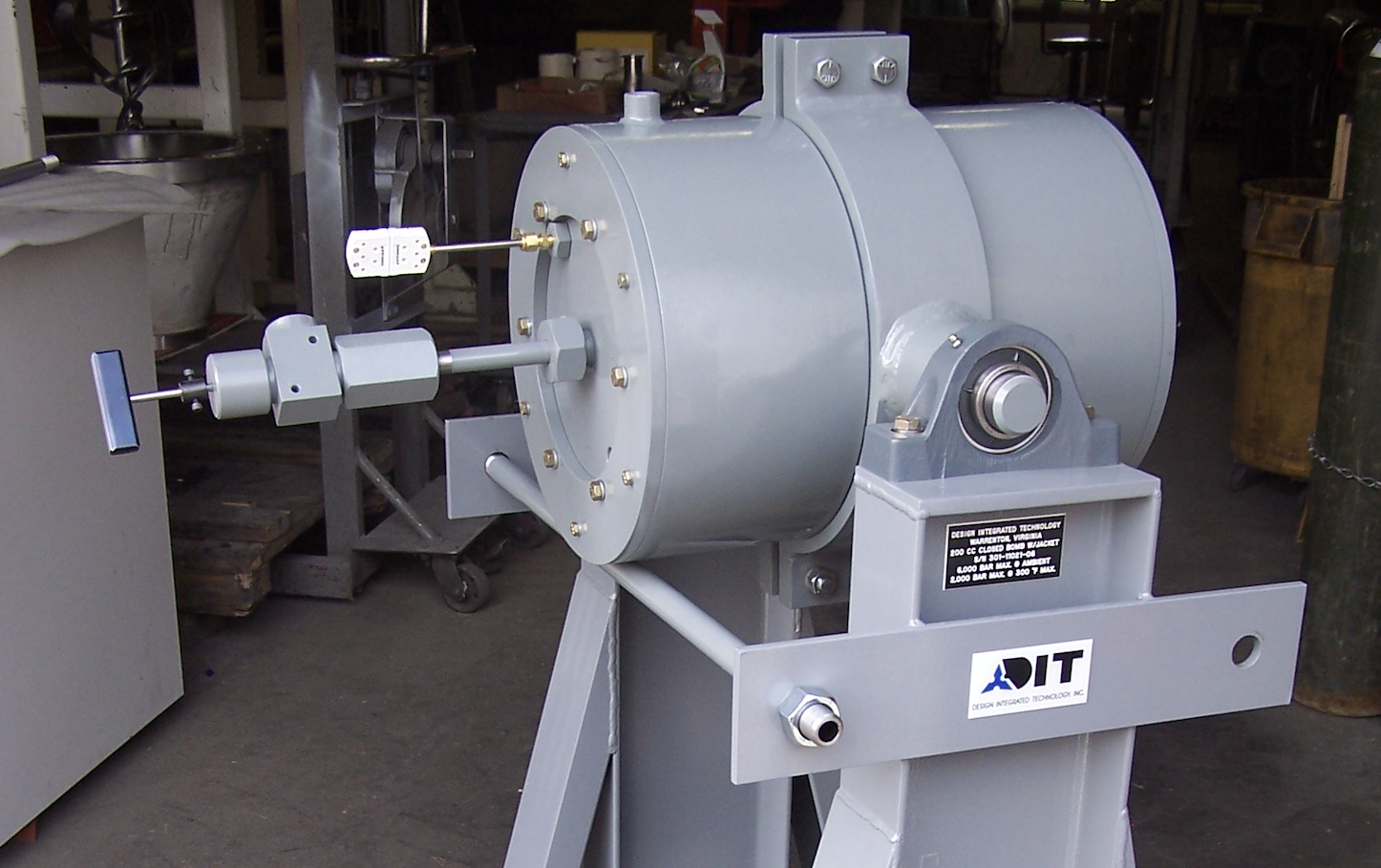

The Closed Bomb (Powder Bomb) is used for determining the quickness and force of a test propellant sample, by a relative or an absolute procedure. It is used primarily for gun propellants. These closed bomb results provide an indication of changes in propellant for quality control and for a possible prediction of the ballistic results of an item using the propellant in question. A variety of sizes, 75cc thru 2,400cc are available with optional monitoring instrumentation and controls.

In December of 2022 DIT acquired the Harwood Engineering “Closed Bomb (Powder Bomb)” technology. DIT has continued to build this same design as well as service spares to previously built Harwood Engineering products.