The Strand Burner System is designed to measure the linear burn rate of solid fuel propellant via the Crawford style pulsed time method. All systems are designed for maximum safety and accuracy and reflect the original intent of MIL-STD-286. Data channels include time, pressure, and temperature. Specific pressure and temperature ranges vary depending on requirements.

Strand Burner

Features & Benefits

The Advantages of the Strand Burner

Key Features

- The system is remote actuated and monitored, combining safety with efficiency of design.

- The system is comprised of a remote control console, located in an operator control room, and a temperature controlled test cell pressurized by a valve rack located in an adjacent room.

- All systems are custom tailored to customer specifications and can meet pressures up to 30ksi and higher.

- The test cell is built from the highest quality materials.

- Single, double, and triple head test cell configurations are offered.

- Temperature Bath houses Test Cell Assembly – regulates temperature which can be remotely controlled and recorded.

- Remote Valve Rack regulates pressure throughout the system, operated via remote control console

- LABVIEW Software, all test data is saved and can be printed or exported to a spreadsheet.

- Gas Booster: Two stage N2 booster can deliver up to 10,000 psi (higher pressures available), features automatic Start/Stop. Shop air filter, regulator, gauge, & speed control valve. Includes two 1.4 cubic feet (39.6 liter) storage tanks with gauge, relief valve, and manual shut-off valves

Product Benfits

- The console controls and monitors the firing process in real-time. In conjunction with the mounted controls, a computer is integrated into the system to allow for data acquisition.

- MIL-STD-286 Style integrating advanced instrumentation and remote data acquisition & control resulting in increased accuracy and safety. Break wire timing method is standard. Systems can be designed for 5,000-30,000 psi at -65 to +180 F. All systems are tailored to customer requirements.

- Optional acoustic transducer amplification system which records a sound trace of the burning sample over time, from which a burn rate is calculated or compared to the mechanical burn rate.

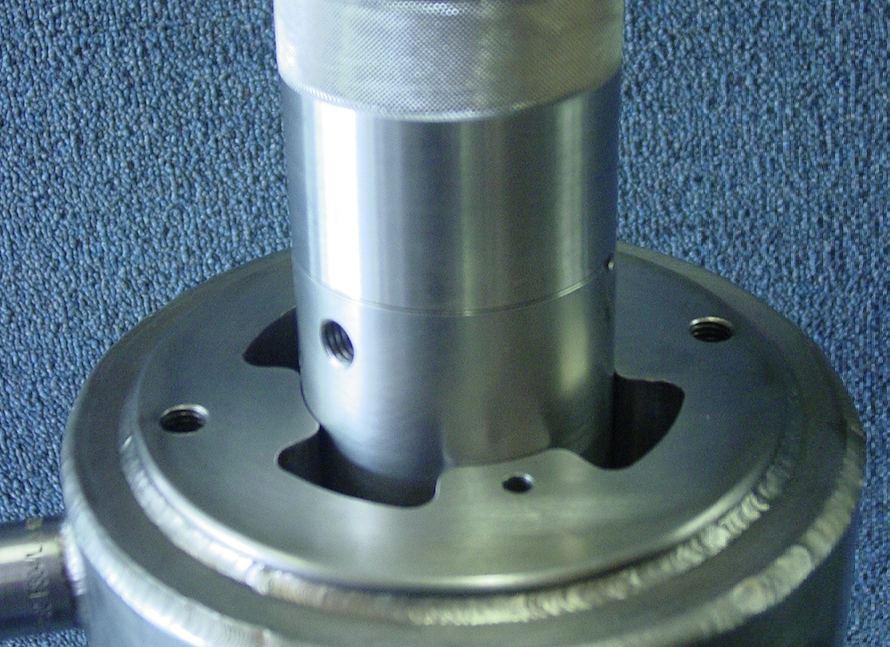

- Test Cell Head: Multiple strand designs allow for simultaneous conditioning and firing of multi-samples which reduces the time to fire and minimizes nitrogen consumption

Additional Product Photos

Request A Quote

DIT is proud to serve it’s clients with first class customer service.

Contact Our Sales Team