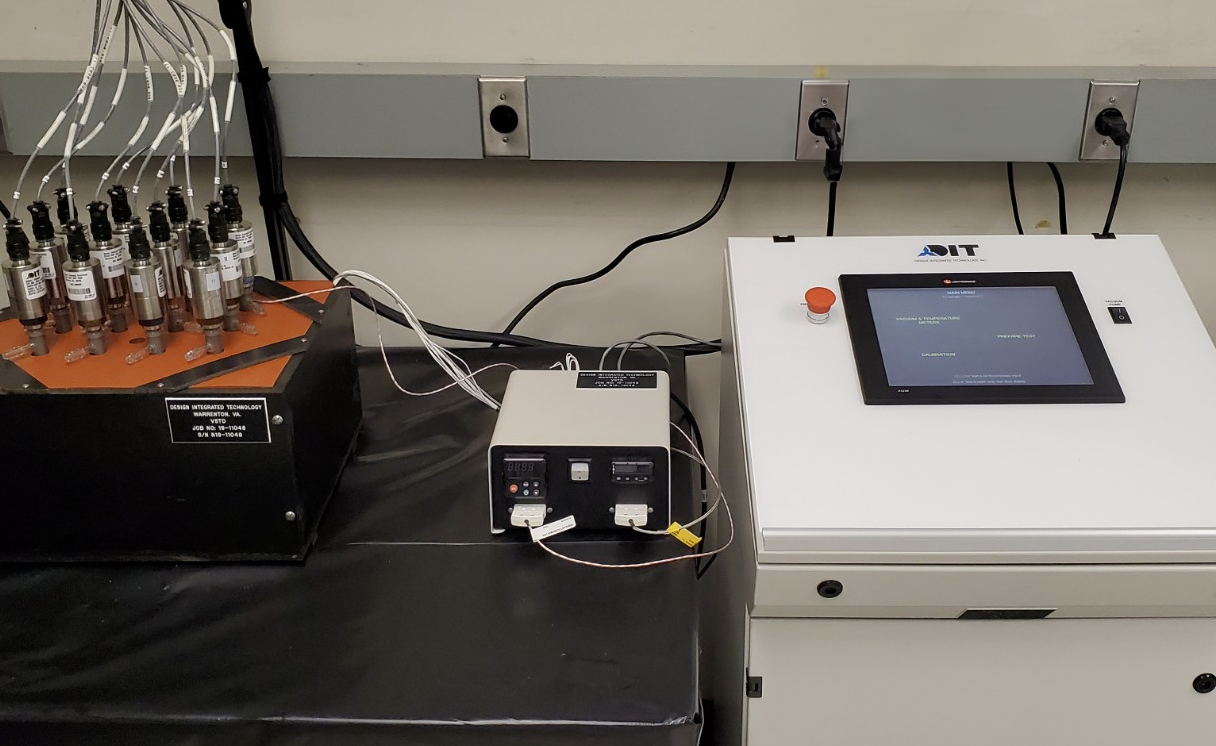

The Vacuum Stability Test Device, also known as VTS (Vacuum Thermal Stability), offers state-of-the-art propellant stability testing in compliance with NATO Stanag 4556. It features a robust design capable of handling multiple samples, a NEMA 4 control console with PLC, and a precisely heated aluminum block for consistent temperatures. Its digital controls maintain temperature within ±0.2°C, and the system includes sensitive pressure transducers for accurate volume change detection. Data is efficiently captured and exportable to spreadsheets, streamlining analysis and reporting processes.

Vacuum Stability Test Device

Features & Benefits

The Advantages of the Vacuum Stability Test Device

Key Features

- NEMA 4 Industrial Control Console w/ PLC

- Electrically heated Aluminum Block with a two RTD’s

- Block housing including insulation to minimize temperature gradients.

- Digital temperature controller with auto tune and ramping features. Capable of controlling temperature to: .2 C.

- Glass sample tubes capable of being fitted to transducers that allows a free volume of 25 cm 2 cm .

- Pressure transducers capable of detection of volume variations of .02 cm , per NATO specs.

- PLC data collection system captures time, pressure, temperature, and other user data. Data is transferred to a computer and can be exported into an excel spreadsheet.

Product Benefits

- Eliminates the use of toxic mercury used in legacy vacuum test stability devices.

- PLC touchscreen for user-friendly test setup

- Records data automatically. Transfer to computer and read in non-proprietary .CSV format or Microsoft Excel.

Request A Quote

DIT is proud to serve it’s clients with first class customer service.

Contact Our Sales Team